Metalworking

Metal processing requires one thing above all: Power. The high-torque motors of Baumüller are optimal for applications that have the highest requirements regarding the torque, such as bending machines. In metal forming, there is a growing trend to select a servo press that is more energy-efficient than hydraulic presses and offers the best quality with a high production capacity. Baumüller has experience in the realization of new servo presses with a pressing force of about 2500 t and in the retrofitting of conventional presses to servo technology.

- Bending

- Pressing

- Milling

- (Pressure) molding

- Cutting

- Welding

- Grinding

- Rotating

► Hydraulics vs. Servo-hydraulics | Calculate your savings!

Link zum Beitrag  ► Time to make the change – Understanding and successfully implementing direct drive technology

► Time to make the change – Understanding and successfully implementing direct drive technology

► Time to make the change – Understanding and successfully implementing direct drive technology

► Time to make the change – Understanding and successfully implementing direct drive technologyReferences:

Are you interested in buying our products?

Write us a message, our sales experts will be happy to advise you.

Our drive electronics for the metal industry:

Our motors for the metal industry:

Our controls for the metal industry:

Our services for the metal industry:

Downloads

Brochures / Flyer

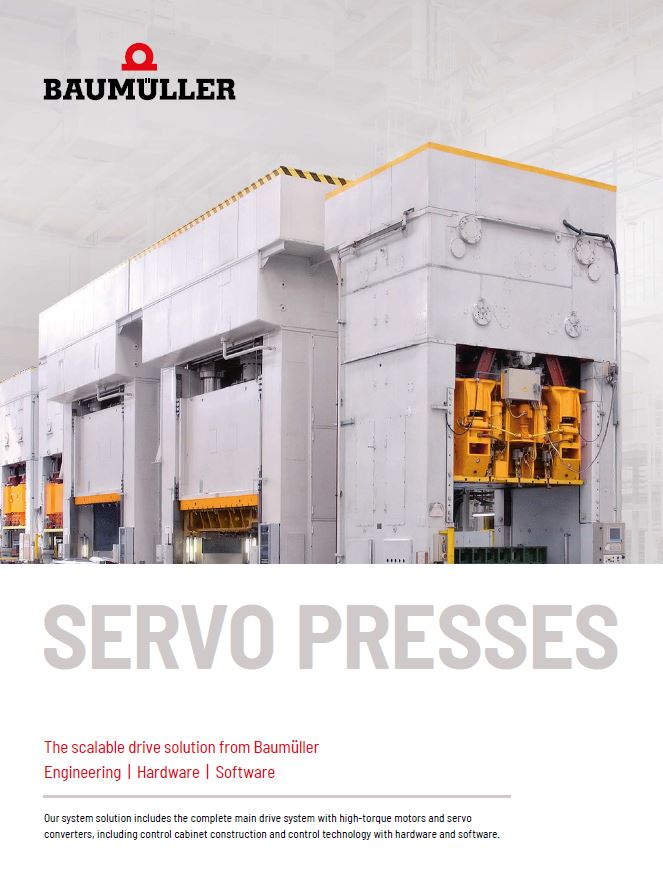

Servo presses

The scalable drive solution from Baumüller

Engineering | Hardware | Software

Engineering | Hardware | Software