With Baumüller you can design your machines to be flexible and highly efficient

We plan and deliver complete automation systems for our customers - from the operating system to the machine control, including software solutions, to drives. The results of our work can be found in almost all branches of mechanical engineering. This is based on scalable components, which can be freely combined and optimally adapted to your machine topology. By using standardized interfaces, your automation solutions from Baumüller are state-of-the-art, future-proof and extendable.

For your automation systems, the choice is yours – determine the extent to which you want to use the Baumüller components, modules and services. Benefit from the possibility of freely combining function modules, technology solutions, and libraries, and optimally adapting them to your needs. Protect your automation know-how with your own libraries; draw on your stored knowledge for new projects and reduce your project planning effort.

Control platforms

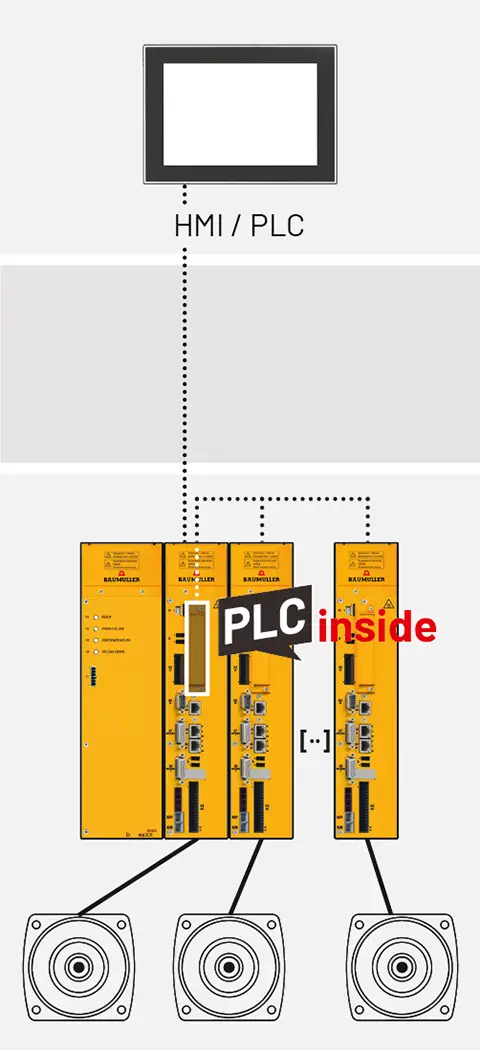

Decentralized concept  Technology function directly in the drive, e.g. for servo-hydraulics in injection molding machines

Technology function directly in the drive, e.g. for servo-hydraulics in injection molding machines

b maXX PLC di:

Highly synchronized motion control with drive-integrated PLC

The drive-integrated b maXX PLC di enables highly synchronized motion control, maximum speeds, and a modular layout of machines and plants.

- Additional hardware in the controller

- Higher performance: minimum cycle times up to 250 μs for highly synchronized motion control

- Modular machines: central or decentralized topologies are possible

- Maximum connectivity: ready for future requirements and IoT

- Data from the drive are provided by an OPC server interface with your own and external systems

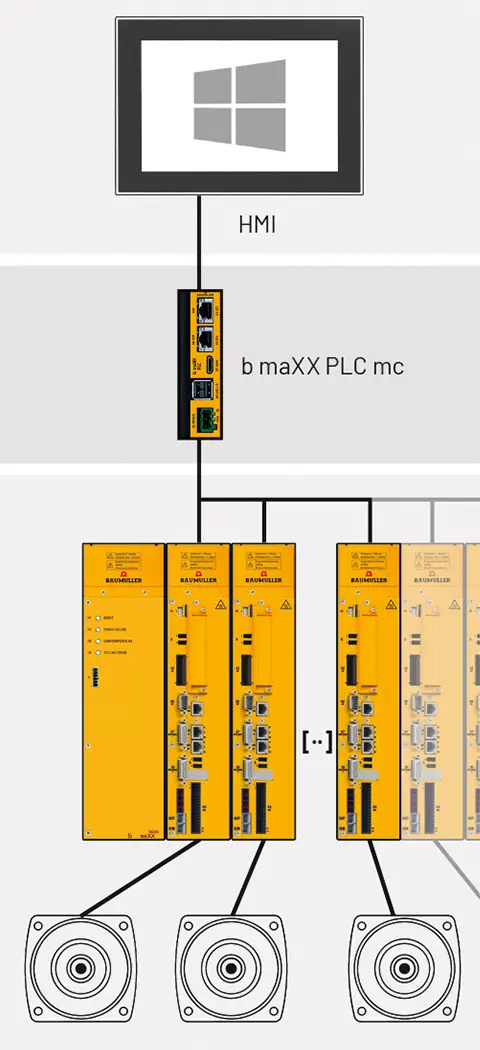

Centralized concept  Technology function in the control unit, e.g. for web processing machines

Technology function in the control unit, e.g. for web processing machines

b maXX PLC mc:

PLC & PC combined

Combines industrial PC and classic PLC control on joint hardware and apart from the actual control tasks, also enables use of the Windows operating system.

- Control cabinet PLC

- Can be used universally for virtually any automation task

- HDMI interface type C

- IP20 stainless steel housing with mounting clips

- WIN 10 IoT 2019 LTSC Enterprise

- Maximum connectivity: ready for future requirements and IoT

- Large internal memory enables the storage and preprocessing of data