Engineering Framework ProMaster

One Framework for All Automation Tasks

The ProMaster Engineering Framework contains the tools for solving all automation tasks: from the drive design to the parameterization, the programming of control units, fieldbus parameterization through to visualization. This applies throughout the entire life cycle, not only during the planning and initial commissioning but also during maintenance.

ProMaster makes engineering more efficient and systematically reduces the extent of work required despite increasing complexity. Defined interfaces, modular machine architectures, and optional extensions result in more efficient automation solutions for flexible use.

An engineering framework for all automation tasks makes processes more efficient, enables faster plant production, improves product quality, and reduces the probability of errors. In addition, it increases the productivity of both the machine manufacturer and the operator.

► Learn more about Smart Engineering in the Baumüller Motion Arena!

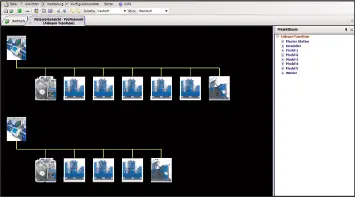

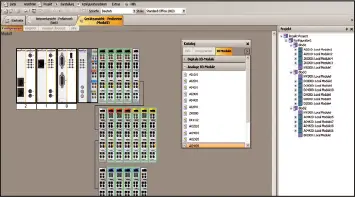

Machine topology

Catalogs, machine module templates

Configurators

Fieldbus communication PLC modules I/O modules (local / remote)

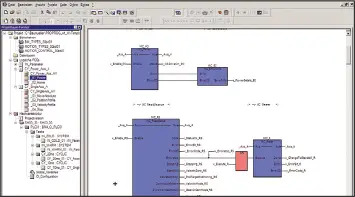

Application creation

PLC acc. to IEC 61131-3, CAM editor (VDI), Visualization, Drive parameterization and operation

Library concept – reusability

- Common database

- User expansion templates

- User is free to structure library

- Structured archiving of expertise acquired in machine modules

- Basic and advanced libraries

- Standardized software elements

- Especially suitable for use in modular system design, with different machine versions and in the context of continuous development

- Easier management and maintenance

Write us a message, our sales experts will be happy to advise you.

Downloads

Automation

ProMaster, Motion Control, IoT Industry 4.0, b maXX HMI, I/O systems